European EN standards can sometimes be too complex for their own good. Despite that, when it comes to using standards as part of a garment selection process, I am great believer in the detail. Not only does a failure to consider detail increase the risk of misunderstanding standards and what they tell you – which might mean workers are less protected than you think, knowing and understanding the detail has benefits. Standards often contain information that can be useful in comparing different garments in terms of their various properties and ensuring you select the best suit for the job.

For example, all protective clothing standards include required testing and classification of key physical or mechanical properties. This can be useful for those selecting protective safety clothing in two ways. This blog looks at the testing of physical properties and how it can be used by users selecting chemical or other protective workwear.

What Mechanical Property Testing Is Required for Chemical Safety Clothing?

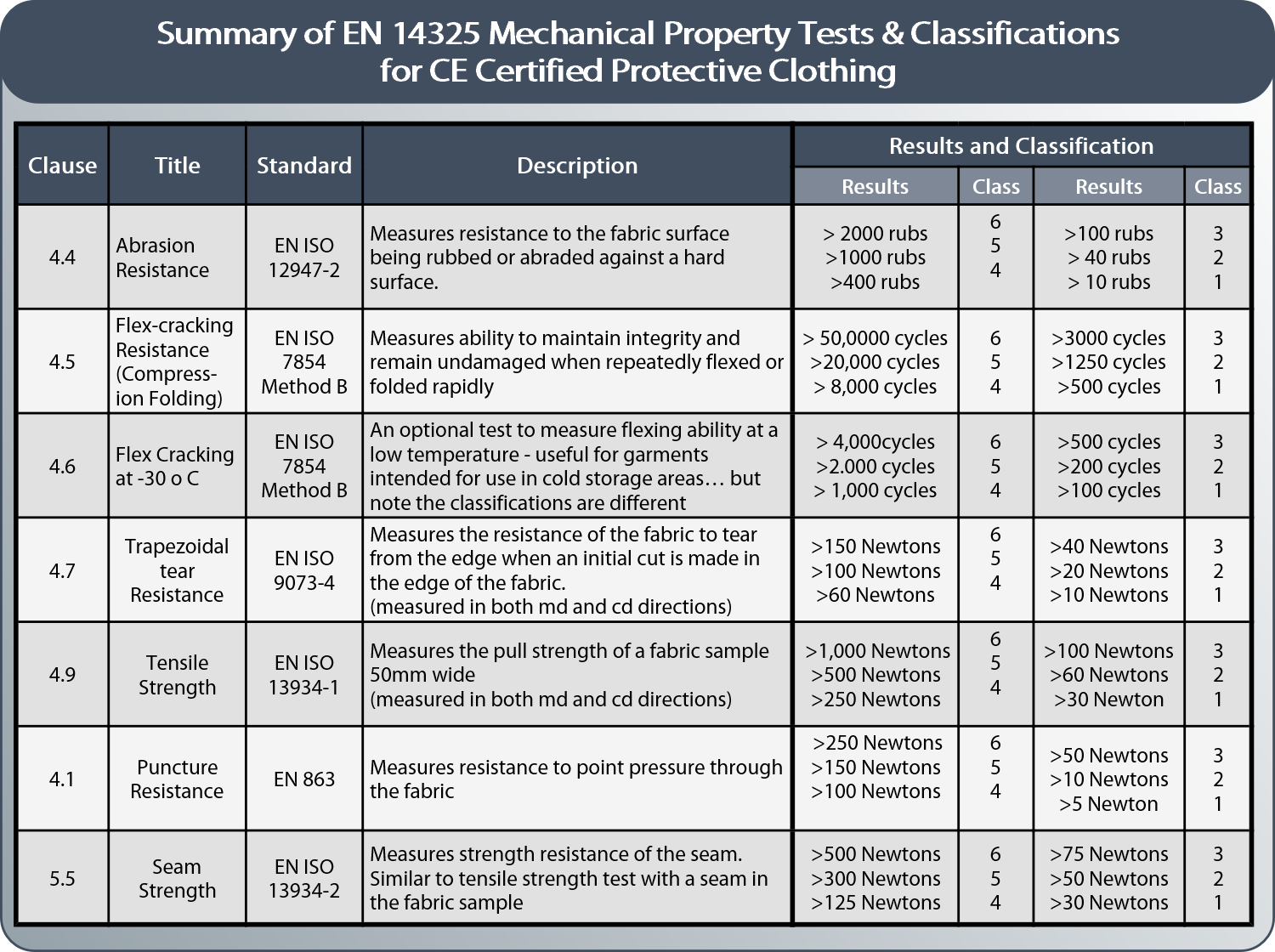

Certification of chemical suits, whether certified for Type 1, 3, 4, 5 or 6, includes a range of tests designed to indicate the performance in terms of the mechanical properties of the fabric and construction. The results of these tests are classified according to classification tables provided in the reference standard EN 14325.

Each product standard lists mechanical properties test requirements by referring to the relevant clause in EN 14325. Each clause relates to a specific test – either describing the test method, or in many cases, referencing a separate test standard which describes the test method. Each clause also includes a classification table to indicate how the results should be classified. There are a number of points worth noting about this system:

- Not all protective clothing standards require testing to all the mechanical properties tests. Those required are indicated in the relevant product standards.

- These same mechanical properties tests are often used across different types of protective clothing. The standards for Type 5 or 6 disposable clothing (EM 13982 and 13034), for Type 3 and 4 chemical suits (EN 14605) and FR workwear (EN 11612) may reference the same mechanical strength tests (though not necessarily via EN 14325).

- In most cases, product standards do not specify a minimum performance requirement for these tests (with some exceptions such as EN 943 for gas-tight suits). Generally, the requirement is to conduct the specified tests and provide the classification achieved with User Instructions. (Note the requirement is to quote the classification achieved – not the actual result)

The table below shows the main mechanical properties tests and classifications:

|

|

| It’s a good question. Wouldn’t it be even more useful for users to have the actual test results rather than a classification? In fact, a classification could serve to disguise differences between products rather than highlight them.For example, the classifications for tear resistance include Class 2, a result between 20N and 40N and Class 3, a result between 40N and 60N. So two different products could have results of 21N and 39N. Clearly the second product has a tear resistance almost double that of the first, yet both would be listed as “Class 2” so in the eyes of users are the same. For this reason, it is useful to obtain the actual result for these tests – not just the classification. Some manufacturers (such as Lakeland) make this information freely available, others don’t. If they don’t, one would have to question, why?

There are two possible reasons for the insistence on classifications rather than results:-

However, the use of classifications rather than actual results will help to average out such variations in test results * There are two reasons for variations in fabric. First, standard specifications for disposable coverall fabric weights generally include an allowance for a variation of +/- 5% or even 10%, so a fabric with a nominal weight of 50gsm could in reality vary between 45gsm and 55gsm – and strength will vary correspondingly. Second, disposable fabrics are constructed of extruded fibers which are laid randomly into a tangled web and bonded into a sheet form. Inevitably this results in areas within the fabric of a greater or lesser concentration of fibers – which also corresponds to variation in mechanical properties (greater concentration of fibers = greater strength). This is particularly noticeable in flash-spun polyethylene fabric (commonly know as Tyvek®). Hold this fabric up to the light and the fibers – along with clear variations in concentration – can be clearly seen with the naked eye. |

How can These Tests be Used in the Selection of Your Chemical Protective Clothing?

There are two distinct uses of the mechanical property tests, first in comparing performance of different garments, and second, in assessing if a garment is most suitable for your application.

1. Use to compare different safety clothing performance

Clearly when selecting between different chemical suit options, a simple comparison of the test results or classifications for different physical properties can provide an easy comparison of relative performance. Garments with higher classifications have better strength properties. Better strength properties means a garment will be more durable – it will resist the stresses and strains of a working environment more effectively and will last longer.

Commonly, cheaper garments feature low classifications in mechanical property tests. It’s a simple equation; the two easiest ways of reducing the cost of protective clothing are to use lighter weight (and therefor cheaper) fabric and to use less of it by making the garment smaller. Generally (though not always – other factors may play a part) lighter weight fabric will be correspondingly weaker. It is no accident that when looking at Type 5 and 6 disposable garments the cheapest in the market rarely achieve mechanical property classifications higher than 1.

How is garment size determined? |

| Clearly effectiveness of protective clothing can be strongly influenced by garment size and styling. And yet there are no European standards that define the actual size of safety clothing. EN 13688, the standard defining the general requirements for all protective clothing describes how sizing should be designated and indicated on the garment label and user instructions, but the actual sizing of garments is entirely determined by the manufacturer.

So an XL from one manufacturer may be different in size from an XL from another. |

(And of course, the second way to reduce cost, using less of it, makes things worse because a smaller garment will be more susceptible to the normal stresses and strains of a working day).

As with all products, the cheapest garment is not always the most cost effective option. If fabric is weak it will tear too easily in use, and once damaged, it is not doing the job of protection it should. And a garment that is half the price does not amount to a saving if it lasts only half as long — as a consequence you are buying twice as many!

2. Use to assess suitability for your application.

An important part of protective clothing selection is to consider the factors relating to your specific application and its environment, and the mechanical property tests are a useful tool in this process.

For example, if your application takes place in an area featuring many sharp edges or corners on which fabric may snag, then choosing a garment that features a higher tear strength resistance classification might be a good idea. Alternatively, where an application involves continuous leaning or rubbing on a surface such as the edge of a table or workbench, a garment with a higher abrasion resistance would be a good choice.

In each case, assessment of the specific parameters of your application and consideration of the mechanical properties that might be important can make a useful contribution to selection of the best protective clothing for the job. It could mean that protective clothing last longer and that workers remain protected as long as they need to be. You can discover more about the types of task and environment factors that might influence garment choice in our Guide to chemical suit selection.

Where Can You Find Information on the Mechanical Properties Test Results?

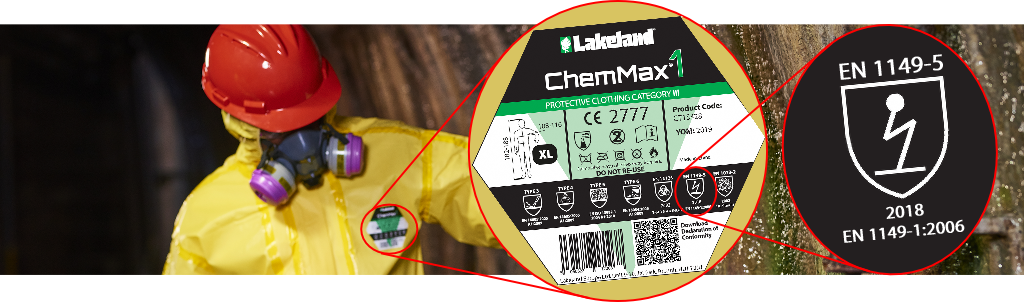

Classifications for required mechanical property tests should be indicated in User Instructions accompanying each garment, and in some cases, in any marketing materials. All product sheets relating to Lakeland CE certified protective clothing include all the relevant classifications and are available from our web site resource page here (along with CE certificates and Declarations of Conformity). In addition, for more detailed analysis we can supply technical data sheets on most products that includes not only the classifications but also the actual test results.

Our policy is to make all such information easily accessible to users. More information means better selection of clothing that is right for the task. If such information is not easily available from manufacturers one can only ask, why?